From the Earth

Bengala Sustainable Mud Dye

Born of Earth, sustained by Nature

From the Earth

Bengala Sustainable Mud Dye

Born of Earth, sustained by Nature

From the Earth

Bengala Sustainable Mud Dye

Born of Earth, sustained by Nature

From the Earth

Bengala Sustainable Mud Dye

Born of Earth, sustained by Nature

From the Earth

Bengala Sustainable Mud Dye

Born of Earth, sustained by Nature

From the Earth

Bengala Sustainable Mud Dye

Born of Earth, sustained by Nature

Bengala is a mud dye made of natural minerals derived from the soil. Using traditional methods and modern technology, it brings us ancient colors as a new sustainable textile dye for fabrics, natural fibers, and paper. Bengala dyeing is a totally different method from plant dyeing and acid (chemical) dyeing. It is the bonding of mineral pigment to the fiber. As the color comes from mineral particles, Bengala dyes also have UV protection– the color won’t fade in the sun!

Iron oxide pigment found in Paleolithic paintings estimated to be 20,000 years old in Lascaux Caves, France and Altamira Caves, Spain.

Bengala is made from iron oxide naturally found in soil. It is said that the greatest quantity of red soil on earth is iron oxide. The name Bengala comes from the Bengal region in India-Bangladesh, where the process was found. An ancient color made from the oldest pigments, this technique has been used since the Old Stone Age. Since Bengala is made from all natural ingredients, you can feel good about using it in your home and it can be safely discarded in your garden.

You only need water. No heat or chemical substances are necessary. You will see that as you knead the fabric in the dye bath, the water starts to become clear because all of the pigments transfer from the water into the fabric. Left over dye solution can simply be drained back into the ground as part of the soil it came from.

Our guide to using Bengala Dye

Bengala Color Chart

PDF Instructions:

Bengala Dyeing Process

Bengala mud dyes work on most fabrics, including cotton, linen, hemp, silk, wool, rayon, polyester, and fiber blends. Unlike many other kinds of plant dyeing methods, it is even possible to dye synthetic fibers such as polyester with Bengala if pre-fixer is used. Fabrics made without fibers, such as vinyl, are not suitable for Bengala dyeing.

Bengala dyes also work on leather. Be aware that the finished surface of the leather becomes matte and sandy, not shiny. You do not need to use a pre-fixer on leather.

One 65 ml bottle of Bengala dye is generally sufficient for an adult-sized t-shirt (about 100 grams), and a 200 ml bottle of Bengala can dye approximately five t-shirts (about 500 grams). It is difficult to give an exact measurement of how much dye you will need, as each fabric will absorb a different amount of dye depending on its structure and fiber content. Fabrics like wool, corduroy, and jersey cotton will absorb more dye, while fabrics made from smoother fibers, like silk and synthetics, will not bond with the dye as readily, and so less dye will be used. Additionally, if you are seeking a lighter shade, you will not need to use as much dye.

Pre-treat your fabric with a pre-fixer for optimal results. Fabric should be damp before dyeing.

- In a bucket, pour in just enough water to cover your fabric.

- Shake the Bengala dye bottle well before using, as the pigment particles will sink to the bottom. Start by adding ½ - 1 tablespoon dye solution to the water and mix thoroughly.

- Add damp fabric to the dye solution and knead the fabric evenly for 3-5 minutes or until the shade you want is achieved. (Note: Like all fabrics, it will appear a few shades darker when wet, and it will dry lighter). If the water is becoming clear, you can add more dye. For delicate materials, like wool and silk, press the fabric gently instead of kneading.

- Remove fabric from the dye vat and roll in a towel to absorb excess moisture. Dry in the sun, or use a tumble dryer, iron, or hair dryer to dry indoors. Do NOT rinse before drying completely.

Mixing alum water with Bengala dye helps prevent felting by skipping the extra steps of rinsing and kneading in the pre-fixer process. Alum works like a pre-fixer by promoting ionization to help the color stick to the wool fabric or yarn more easily.

Note: Superwash wool, which has been processed to remove the scales on the wool fiber to prevent felting and tangling, dyes better with pre-fixer. The smoother fiber of superwash wool is harder for Bengala dyes to stick to, and as it won’t felt, we recommend pre-fixer.

Weigh the material (fabric, raw wool, yarn) you are going to dye. Put tap water that is 10 times the weight of the fabric in a bucket. Measure alum to be 3% of the solution. (For example, if you are dyeing 100 grams of fabric, you will use 1 kg of water and 3 grams of alum). Add alum to water and mix well. Pour the amount of dye you would like and mix well. Soak the material in the dye bath and knead it lightly. Note: Excessive kneading will cause felting.

The dye solution becomes clear as the wool absorbs the dye and alum mixture. If you would like a deeper color, for best results, we recommend making a new dye bath with fresh alum water to add more dye to your wool. Squeeze the dyed fiber lightly and then wrap in a towel to remove excess water. Dry the fiber well. Do not rinse before drying completely. Fiber can be washed after it is thoroughly dried.

Excessive use causes the pigments to adhere to each other, preventing good dyeing results. Please use the proper amount.

Bengala is like watercolors. You can mix the colors as you like. If you would like a lighter shade, start with a small amount of dye in the water. You can add color anytime. Bengala dyes can be mixed in the same dye vat, or the colors can be overdyed/layered in different dye vats.

You can make blue shades by adding Aijozome Indigo to the dye solution. To make pastel shades, you can mix with K-2 Gohun (a white color from natural titanium dioxide).

Yes! We recommend using a pre-fixer for the tie-dye technique to improve the contrast between the dyed and resisted areas of the fabric. Bengala dyeing is not a soak dye or dip dye. You have to knead the fabric in the dye bath until it reaches your desired color.

Drawing with Bengala dyes on fabric is like watercolor painting.Use a brush, and dilute the dye with water for your desired tone.You can paint with Bengala on dry fabric, and if you would like to blur the color, you can wet the fabric partially while painting.

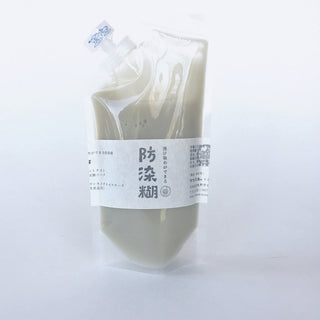

Bengala is great for decorating fabric with stamps to create block prints or stencil with unique designs. Just pour the amount of dye you want to use into a palette. If you would like the dye mixture to be thicker, you can either wait and let it dry out a little, or you can mix in a thickening agent (read How to Use Thickener). To thin the dye, just mix in a little water. For a crisp line, we recommend that you print on dry fabric. If you would like to blur the color, you can wet the fabric partially while painting.

After you are finished painting your designs, make sure to allow the fabric to dry thoroughly in the sun or under an iron or hair dryer before rinsing.

FAQ

Loop of the Loom is proud to offer Bengala products as an authorized dealer of Kosyokunobi since 2012.

The philosophy of Kosyokunobi is to revive ancient techniques to promote environmentally-conscious, all-natural beauty, connecting us to the earth through material and color. Through extensive research and development, Kosyokunobi succeeded in producing various natural colors only from soil.

Kosyokunobi launched in 1991 as a new division of Nakajima Co. for textile dye. Nakajima Co. was established in 1965 in Japan as a producer of Bengala paints for temples, shrines, and wooden dwellings. Natural Bengala stains were a mainstay for Japanese wooden buildings because of their superior characteristics of protection against termites and harmful UV rays. As housing styles have modernized in Japan, the cultural use of Bengala for painting homes has decreased as people have chosen petroleum-based paints instead. Our new global movement towards more natural ways of life is turning back to traditional wisdom and more eco-friendly choices.

Kosyokunobi in osaka, japan

Using Pre-fixer for Bengala Dyeing

Pre-fixer is an ionizing agent that helps bond the Bengala pigments securely to the fiber. Our pre-fixer is a non-toxic cationic surfactant, a raw material used for hair conditioner, air purifier, and fabric softener. The pre-fixer is an ammonium salt, which carries steady positive ions formed by the reaction of ammonia and acid. The pre-fixer is a completely non-toxic, man-made salt. If you prefer to use 100% natural ingredients, please read "How to dye the 100% natural way".

Bengala dyeing uses ionic reactions to adhere the mineral (Iron III oxide) pigment particles to textiles. Like a magnet, the positively-charged ions of the pre-fixer attract the negatively-charged ions of the Bengala dye.

This pre-fixer does not work without water (H2O). Water serves as a mediator between + (positive ion) and – (negative ion) and makes them friends! It is only possible under the water. Water is important and indispensable for dyeing.

We recommend using pre-fixer before Bengala dyeing all fibers except wool.*

The colors of your fabric will appear more vibrant and patterns created with shibori (tie-dye) techniques will be clearer and longer lasting if the fabric is treated with the pre-fixer. Bengala can dye almost anything, even synthetic material, by using the pre-fixer. Especially for items like clothing, which will be washed repeatedly and withstand wear-and-tear, we definitely recommend using pre-fixer to allow your beautiful dyework to last longer.

For items that will not be washed frequently, it is less important to use pre-fixer. For items like starched canvas and reusable shopping bags, we have found that the pre-fixer will change the texture of the fabric, and if these items will not be washed regularly, you may skip the pre-fixer.

*If you plan to dye wool, we recommend using alum water instead to prevent felting. Read our instructions for alum wool dyeing.

Please see our PDF Instructions for more information and tips. If you have sensitive skin, we recommend that you wear gloves.

- Weigh your fabric.

- Mix the pre-fixer solution: Use 10 times the weight of the fabric in water and 3% the weight of the fabric in pre-fixer. Mix well. (For example, if your fabric weighs 100 grams, you will use 1 kg of water and 3 grams of pre-fixer.)

- Add damp fabric to pre-fixer solution.

- Knead and stir the fabric for 1-2 minutes in the pre-fixer solution.

- Remove the fabric and wring out well.

- Rinse the fabric twice in clean water.

- Wring out the fabric well.

You can dye the fabric immediately after following these steps, or you can allow the treated fabric to dry and dye with Bengala at a later date. Be sure to wet the fabric before dyeing.

Gojiru: Gojiru (soybean extract) treatment is a technique often used for plant dyeing. It uses proteins in the liquid residue from boiled soybeans to pre-fix the fabric and help the fabric absorb the pigments. In ancient times, Gojiru treatment was also used for Bengala dyeing as a pre-fixer. It is not an ideal method because it takes a lot of time and effort to prepare the soybean extract, such as steaming and squeezing the beans, and the dyed fabric treated with Gojiru requires one year of rest to set the color.

Alum Water: Using alum water to pre-treat your fabric is easier than using Gojiru, and the best way to pre-treat wool products to prevent felting. Fabrics treated with alum water are still lighter in tone than those treated with pre-fixer. Do not add too much alum solution in the dye bath. The excessive density of alum induces a bond between the pigments, not on the fabric. To make alum water, mix water 10 times the weight of the fabric with alum, measuring 3% the weight of the fabric. For example, to treat 100 grams of fabric, use 1 kg of water and 3 grams of alum.

*Although potassium alum exists as a natural mineral, the forms commonly available are industrially synthesized in order to guarantee purity and stability.

Safety & Storage

Kosyokunobi has been producing natural dyes and paints for four generations, developing safe living with natural clothing and houses using Bengala. As a small, family-run business, Kosyokunobi has not pursued expensive certifications or testing.

After reviewing Kosyokunobi's Material Safety Data Sheet (MSDS), proving the materials do not contain lead or cadmium, and based on our extensive experience with these dyes, we believe that Bengala dyes are very safe– safe enough to use on textiles for babies, and safe and fun to use together with your family. People with extremely sensitive skin may want to wear gloves while using Bengala dyes, and be mindful while wearing Bengala-dyed textiles.

One of the ingredients of Bengala dye is hypoallergenic natural rubber latex. Latex is a sap naturally produced by plants, and this natural latex is non-toxic. The latex used in Bengala dyes has been processed to remove the allergen. Latex is optimal for fixing Bengala pigment to the fabric surface because Bengala is a large, irregularly-sized pigment, and the latex penetrates into the gaps and adheres the pigments to the fibers. The fabric remains soft and the latex does not crystallize like synthetic rubbers.

The leftover dye solution can be stored up to 5 days in the refrigerator. Opened dye bottles can be stored in a cool place for 1 year after opening.

Bengala may stain very pale skin, but will wash off after a day with mild soap and water. Most people will not experience any staining on their skin. But remember, your clothing will be dyed if they are unprotected.

You can easily remove any Bengala stains on your bucket with the gentle application of dish soap. There is no need to scrub– the ions of the soap catch the Bengala pigment

After-Dye Care & Washing

Do not wash the fabric right after dyeing– it must be completely dried first. You can dry the fabric in the sun, tumble dryer, or use an iron after hanging to dry if needed. Once dried, it’s ready to wear!

After the fabric has completely dried, if the color is dark, it can be rinsed before wearing to avoid any color rubbing off. Color on your skin will not stain and will come off with gentle soap and water. For the first few washes, wash separately from other clothing to avoid staining other garments. Afterwards, you can wash it in the washing machine like any other item of clothing. As Bengala is a natural material, it's not as long-lasting as synthetic dye. But Bengala is much stronger and longer-lasting compared with other natural dyes. Bengala is also more light-fast than other dyes, as it has some UV protection.

Cloth of Time

Chronicle of craftsmanship with ancient dye from Japan

Cloth of Time

Chronicle of craftsmanship with ancient dye from Japan

Unlimited Creativity with Bengala Dye

Turn traditional techniques into modern designs. Reuse and dye household items with eco-friendly Bengala colors—bringing joy to you and the planet.

Itajime Shibori

Japanese board-clamped resist dyeing

Itajime Shibori

Japanese board-clamped resist dyeing

Itome Shibori

Thread-bound resist dyeing

Itome Shibori

Thread-bound resist dyeing

Hikizome

Brush resist dyeing using resist paste with a hake

Hikizome

Brush resist dyeing using resist paste with a hake

Ombré dyeing

Creating a gradient of multiple colors

Ombré dyeing

Creating a gradient of multiple colors

Skein dyeing

Coloring wool yarn by adding alum water

Skein dyeing

Coloring wool yarn by adding alum water

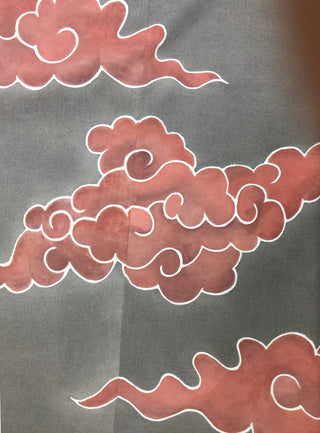

Tsutsugaki

Japanese freehand resist dyeing with resist paste

Tsutsugaki

Japanese freehand resist dyeing with resist paste

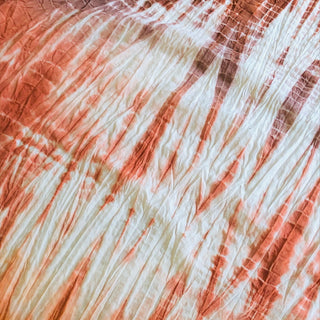

Shibori

Tie dyeing

Shibori

Tie dyeing

Wood Painting

Application of wood finish with added oil

Wood Painting

Application of wood finish with added oil

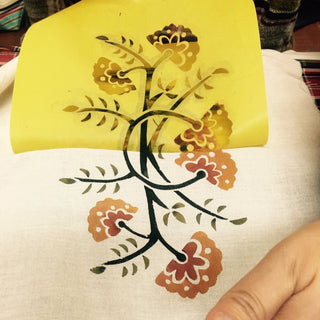

Katazome

Japanese stencil resist dyeing using thickener

Katazome

Japanese stencil resist dyeing using thickener

Tsutsugaki

Japanese freehand resist dyeing with rice paste

Tsutsugaki

Japanese freehand resist dyeing with rice paste

Yarn Dyeing

Coloring cotton yarn with a brush

Yarn Dyeing

Coloring cotton yarn with a brush

Itome Shibori

Thread-bound resist dyeing on pleats

Itome Shibori

Thread-bound resist dyeing on pleats

Stencil

Coloring through a water-resistant stencil using a thickener

Stencil

Coloring through a water-resistant stencil using a thickener

Exterior Painting

Application of paint mixed with oil

Exterior Painting

Application of paint mixed with oil

Katazome

Japanese stencil resist dyeing using thickener

Katazome

Japanese stencil resist dyeing using thickener

Wood Block Printing

Printing with wooden blocks using thickener

Wood Block Printing

Printing with wooden blocks using thickener

Lotus Flower Dyeing

Board-clamped with a special pattern

Lotus Flower Dyeing

Board-clamped with a special pattern

Shop Bengala Natural Dyes

- +7 more